TTT® Enzyme Composting Technology: 3 Hours To Produce Organic Fertilizer!

- Category : Other

- Date : 2021-06-03

- views : 3584

TTT® Technology, a revolutionary “enzyme-based” organic waste treatment process, was developed by Academician Dr. Chiu-Chung Young. It simplifies the traditional microbial composting method that is adversely associated with long duration and multiple types of environmental pollution. To transform this academic breakthrough into real world applications, Dr. Young established Tetanti AgriBiotech Inc. in an attempt to solve this centuries-old problem. Tetanti AgriBiotech Inc. is a spin-out company from the Taiwan Startup Institute of the Ministry of Science and Technology and National Chung-Hsing University, the main purpose of which is to produce various patented targeted enzymes. TTT® Technology utilizes targeted enzymes and a combination of machinery, with which organic wastes are stabilized and maturized into stable and high-quality organic fertilizers within 3 hours. In addition, the organic fertilizer is mostly free of pathogens, insect eggs and grass seeds after high temperature sterilization, and thus is safe and eco-friendly. TTT® Technology is effective with reasonable cost, and the process avoids the generation of bad smell and secondary wastes. It is a comprehensive solution for organic waste recycling and environmental protection with space- and time-efficiency.

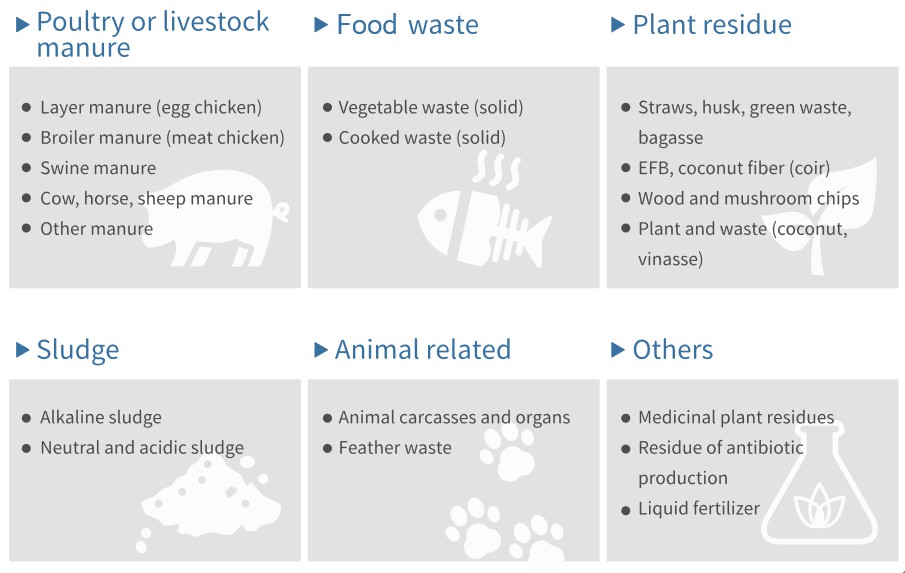

Tetanti' s founder Academician Dr. Young’s R&D team possesses over 8,000 strains and 2,500 species of functional bacterial stock, and is the source of the TTT® targeted enzymes. With this huge collection, we can custom-make the most suitable mixture of targeted enzymes for the management of various agricultural, industrial and municipal organic wastes, such as poultry and livestock manure, animal and plant wastes, herb residues, kitchen waste and related organic wastes (Figure 1). This threshold allows us to stand out as the leader in the field of organic waste management.

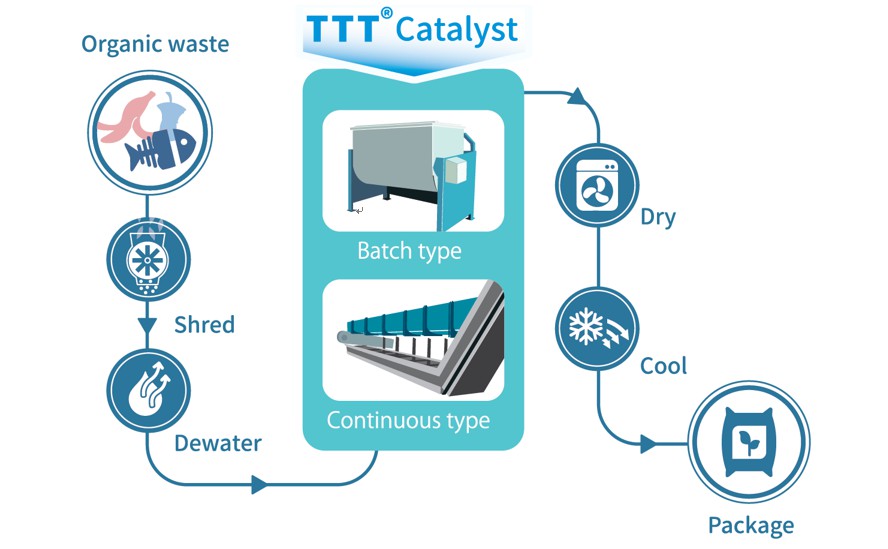

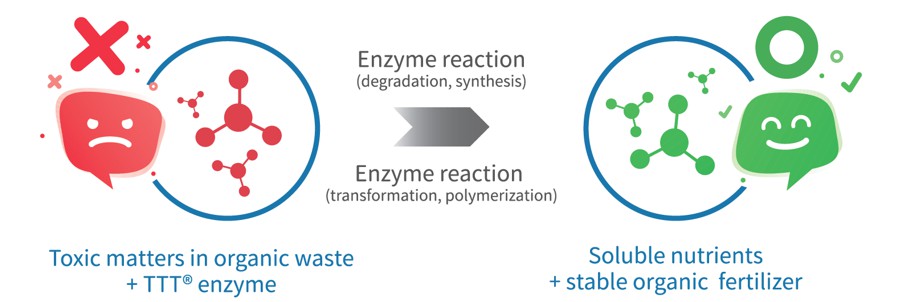

Under the leadership of Academician Dr. Young, in addition to pioneering the production of TTT® targeted enzymes for organic waste treatment, Tetanti provides organic waste treatment process planning services (Figure 2). With the combined use of TTT® targeted enzymes and machinery, it can overcome the limitations of the traditional composting method, producing stabilized and maturized organic matter within 3 hours, and transforming organic wastes into high-efficiency organic fertilizers (Figure 3).

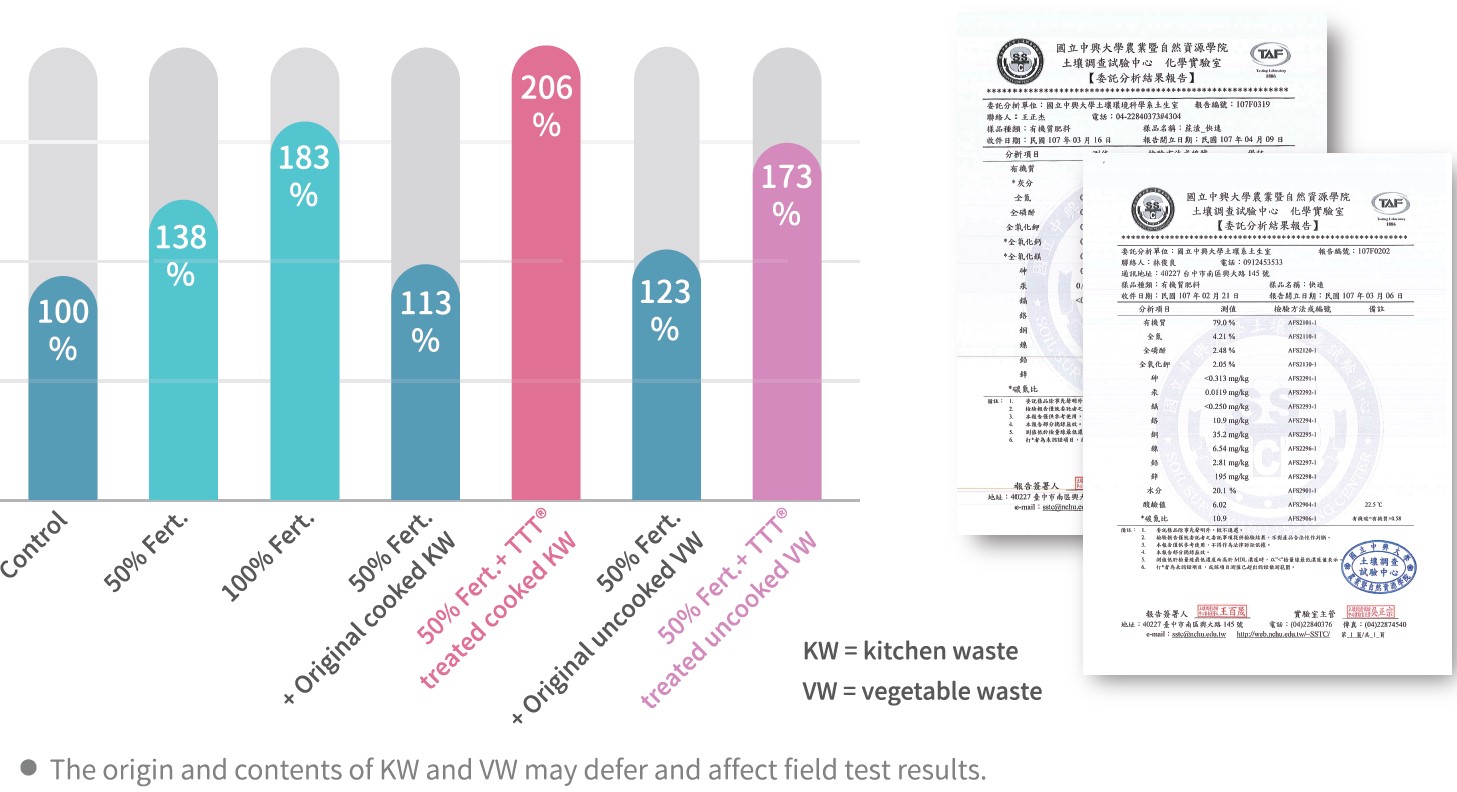

The organic fertilizer products made by TTT® Technology have been verified by many field trials to prove that it can significantly increase crop yield and simultaneously reduce the application of chemical fertilizers (Figure 4).

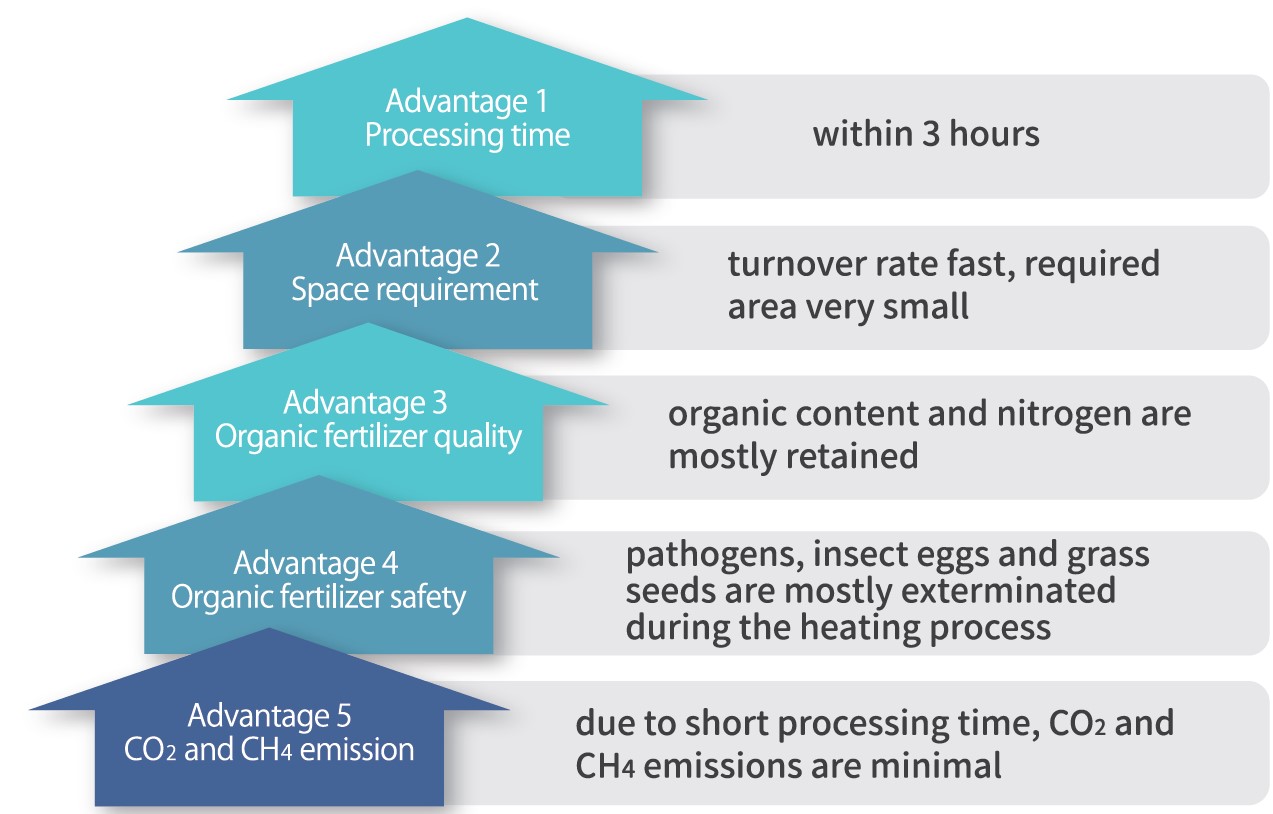

TTT® technology can greatly improve the maturization process of organic matter over 100 fold and can reduce pollution and increase product safety. The production process solves the odor, waste water, large area demand and time-consuming problems that are normally associated with traditional composting (Figure 5).

Tetanti AgriBiotech was awarded "Taiwan's 10 Coolest Technology Innovation Team" in 2019 and was interviewed by Discovery Channel, which filmed the program "Taiwan Revealed: Agricultural Technology" in 2020 (video link: https://reurl.cc/E27pp0). Tetanti will "Think Globally, Act Locally,” and we will stand firm in the circular economy trend. In response to the stringent environmental regulations and carbon emission issues around the world, TTT® Technology will play an important key role in making agricultural sustainability no longer just a slogan! With solving agricultural and environmental issues as our vision, recycling agriculture as the core concept, and with the consolidation of numerous exceptional research outcomes and innovative technologies, our team’s ultimate value is to achieve the enrichment of our soil and environmental recycling as a whole.